DFA

Enhancing Manufacturability and Testability

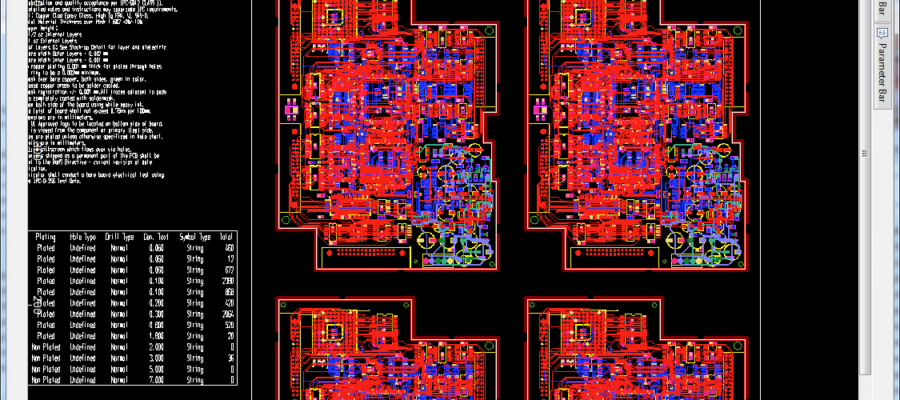

At OmCAD, we incorporate Design for Assembly (DFA) and Design for Testability (DFT) to ensure that every PCB is not only high-performing but also easy to assemble and thoroughly testable—critical factors for production success and long-term reliability.

Why DFA & DFT Matter

- DFA ensures that the PCB design is optimized for smooth, error-free assembly. Poor component placement, inaccessible pads, or incorrect footprints can lead to costly rework and yield issues.

- DFT focuses on simplifying how the PCB can be tested after production. Without proper test access and strategy, identifying faults becomes time-consuming, expensive, and sometimes impossible.

These methodologies reduce time-to-market, lower production costs, and improve product quality by addressing issues before they reach manufacturing or testing.

How We Do It at OmCAD

- DFA Implementation

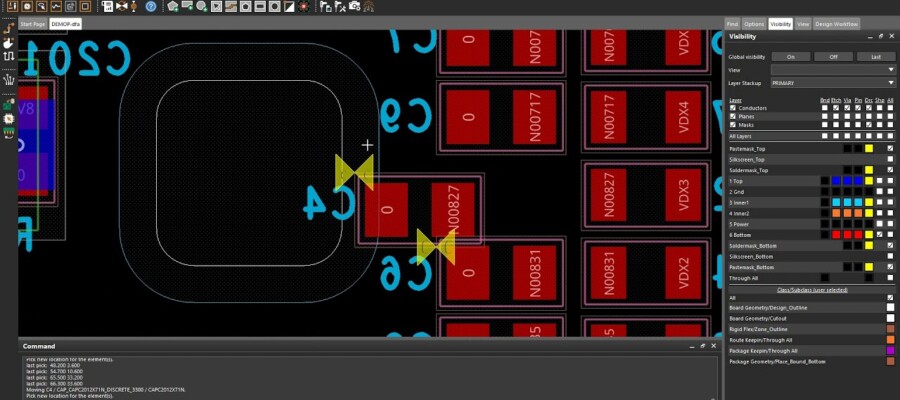

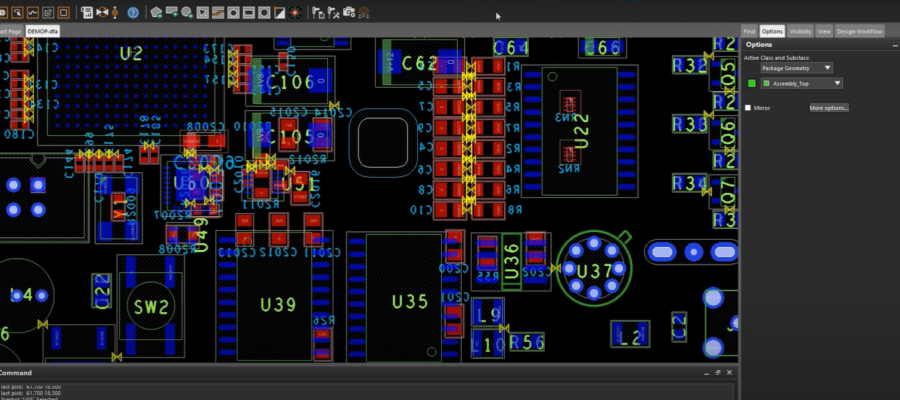

- Check for proper spacing between components and mechanical clearances

- Optimize orientation and accessibility for pick-and-place machines

- Ensure correct footprint standards and solderability

- Analyse thermal relief and via locations for efficient soldering

- DFT Implementation

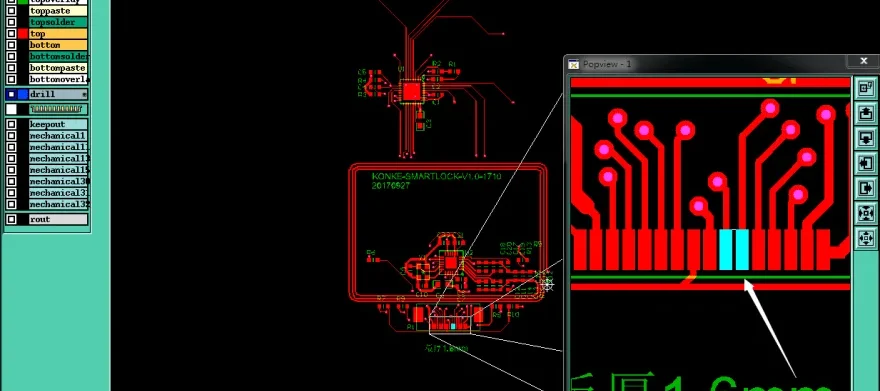

- Include test points and boundary scan support (JTAG, ICT)

- Ensure accessibility for in-circuit and functional testing

- Validate signal paths for voltage/current test coverage

- Simulate fault models and analyse test coverage percentages

By embedding DFA and DFT checks early in the design cycle using industry tools and IPC guidelines, OmCAD helps clients avoid late-stage surprises and ensures a smooth transition from design to manufacturing and testing.